Regardless whether you home is old or new, you need to be aware of potential electrical issues that may occur within your home. Some issues, like the use of aluminum conductors for house wiring, can cause potential damage to your home’s electrical panel, and, in certain situations, may lead to a devastating house fire. The best way to combat these issues is to schedule periodic inspections of your electrical system to ensure its optimal performance. To illustrate this point, here is a story Mike Farrell, president of Grandview Lending, recently heard from his good friend, Marchael Page.

In October 2016, Page was helping his friend Bill with the installation of an irrigation system at Bill’s Carmel, Ind., home. They had run out to pick up some pipe fittings, and when they returned about an hour later, Bill’s garage door opener wasn’t working. When they let themselves in through the side garage door, they immediately smelled a burning aroma and saw a smoky haze in the air. As a retired industrial and commercial construction manager who used to manage projects for large electrical companies, Page decided to look at the electrical panel, which he discovered was covered in smoke residue.

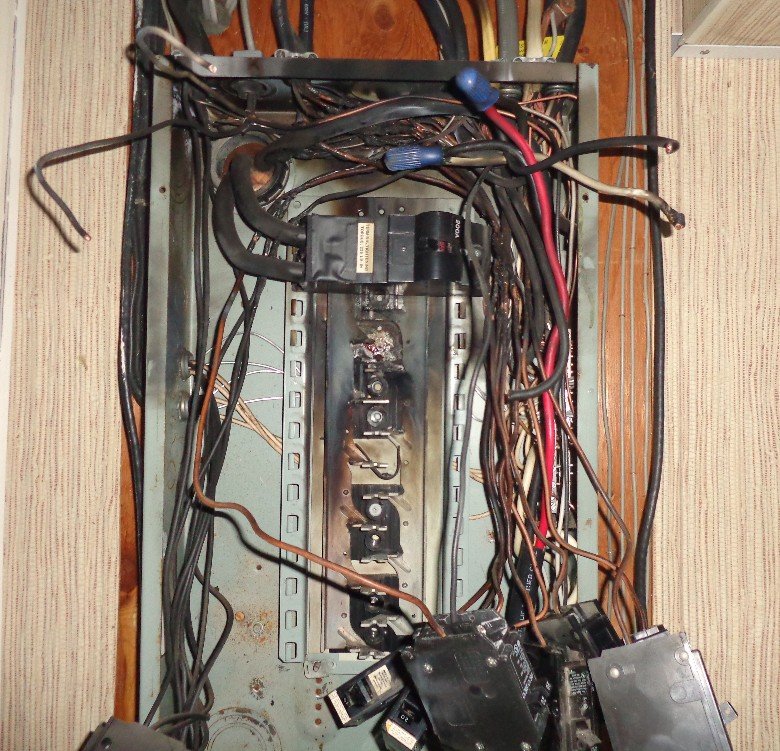

Upon removing the panel cover, Page found that four branch breakers had tripped, the main circuit breaker had tripped, and the branch wiring was severely burned from the breaker connection point to the top of the panel enclosure. Additionally, the 120-volt circuit wires had welded to the neutral and ground wires. Page removed the branch breakers and found the center, vertical aluminum bus exposed and melted by intense heat. (See the main photo.)

“I’ve seen a lot of things in my career, but I had never seen anything like this before,” said Page, who worked in project management for over 45 years and now does part-time consulting and electrical work.

What Caused the Problem?

Page attributed this electrical panel failure to use of aluminum conductors for house wiring. In the late 1960s and early ‘70s, copper become more expensive for electrical use. Therefore, to save money, many home contractors started using aluminum conductors for house wiring instead. This trend of using small aluminum branch wiring continued for a brief time until the problems with it became evident.

Additionally, during this era, many contractors used aluminum bus as well in electrical panels. This aluminum bus wasn’t plated in tin, so it caused poor connectivity and subsequent failure.

“

While aluminum conductors are an adequate current-carrying conductor, I prefer to use copper conductors instead,” Page said. “The metallurgy of aluminum is softer than copper. Copper has a slightly higher current-carrying capacity compared to aluminum.”

Therefore, when you use an aluminum conductor, with time, the terminals on circuit breakers have less tension due to the compression of the aluminum conductor at the terminal. This reduction in tension causes poor conductivity, and, ultimately, heat at the terminal which migrates throughout the conductor. As it begins to overheat, the branch breakers trip first. Then, as the heat compounds, the main circuit breaker trips to open the circuit.

“If the main breaker had been defective from age or manufacturer issues, it would not have tripped and opened the circuit,” Page said. “Then, it could have caused a house fire. Fortunately, the main breaker did its job.” However, the overheating did cause smoke to occur and filter through the house as the aluminum bus and wiring melted.

In this situation, Page said it’s difficult to determine what caused the failure in Bill’s electrical panel – the aluminum wire or the circuit breaker connection to the aluminum bus. However, many professional contractors, who Page shared the story with, believed the overheating was due to the aluminum bus. Regardless, Page ended up replacing the panel and the damaged wiring in Bill’s home.

What Can You Do?

If you have a home that was constructed during the late ‘60s and early ‘70s, Page recommends that you have your home’s electrical panel inspected by a professional electrician about every five years. While many aluminum bus, conductor and wiring systems are likely working fine, it doesn’t hurt to have them inspected. If issues of overloading and/or hot spots are found in the panel, you should have it replaced.

Additionally, Page recommends that all homeowners have their electrical panels inspected periodically to make sure they’re operating correctly. “Be aware of what is going on in your house,” Page said. “If you notice anything unusual like flickering, have it checked out by an electrician. If you don’t have ground-fault circuit interrupter (GFCI) outlets installed in your kitchen, basement, bathrooms, or exterior, get them installed to prevent possible electrical shock or electrocution.”

Page also suggests having the conductors tightened in all aluminum light switches and electrical outlets in your home every five years. Because, as Page said, “no one ever does that.”

By taking these precautions, you can hopefully prevent an electrical panel meltdown like the one Bill experienced in his home.

Looking to Buy a Home?

When buying a home, maintenance can be an important issue to many home buyers. A home inspection can help you uncover any electrical or other system issues with a home you’re purchasing.

Another important issue to homebuyers is finding the right mortgage. As a mortgage broker firm, the mortgage experts at Grandview Lending can offer you more mortgage options compared to traditional lenders. Contact us today for more information about our many mortgage solutions to determine what works best for your situation.

Photos: Marchael Page

Do you know how much home you can afford?

Most people don’t... Find out in 10 minutes.

Today's Mortgage Rates

Leave a Reply